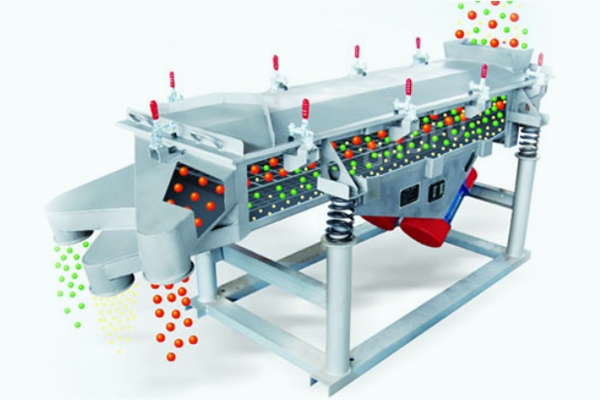

Multi-layer Linear Vibrating Screen Machine is an efficient new screening equipment, which widely used in mining, coal, metallurgy, building materials industry, two sets of horizontal vibration motor to be power source, so that the screened material was tossed in the sieve, while forward in a straight line into the screening machine’s discharging outlet. It can be supplied of different sizes depending on capacity required. And can be supplied of multi-layer as requirements of screening aim. Inlets, outlets and legs can be customized to fit your installation requirements.