| Model |

Material |

Screen cage size(mm)

(diameter*length) |

Screen material |

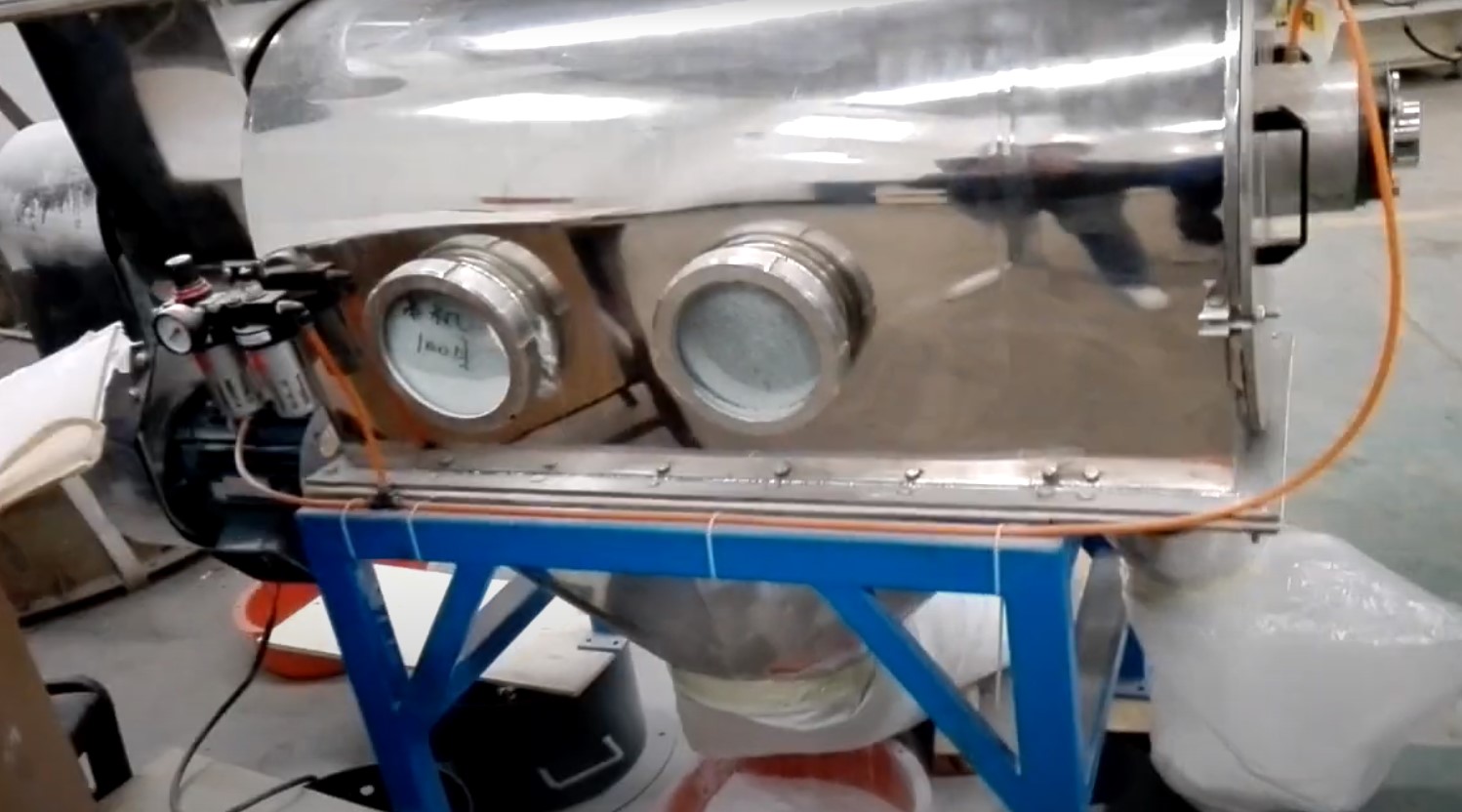

| WSA-18-65 |

Q235A Carbon steel |

180mm*650mm |

Stainless steel or

Nylon screen |

| SUS Stainless steel |

180mm*650mm |

| WSA-30-100 |

Q235A Carbon steel |

300mm*1000mm |

| SUS Stainless steel |

300mm*1000mm |

Spare parts:

1. Screen: Nylon screen and Stainless steel

The two types of screen meet GMP standard. According to different medicine powder, we could choose different model of screen cage in order to receive better effect.

2. Finished Screen cage: Nylon model and Stainless steel model

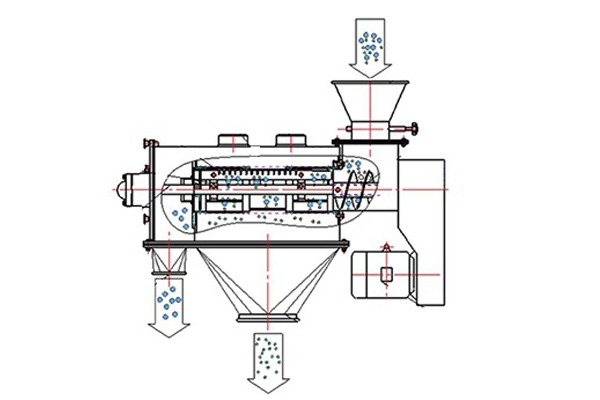

Application

Centrifugal sifter is especially suitable for grinding plant powder, Such as: Chinese herbal medicine powder; Spices: curry powder, ginger powder, garlic powder, chili powder, pepper powder material etc. Cosmetics, mica powder, pearl pigment superfine powder and so on.