As we all know, most kinds of vibrating and screening machines are not waterproof, if the water flow in machines or the whole machines are always wet, as a consequent the vibrating motor will break down, especially when we reuse the vibrating and screening machines after they several months shut down. So what measures should we take to prevent water into Direct Discharge Vibrating Sifter?

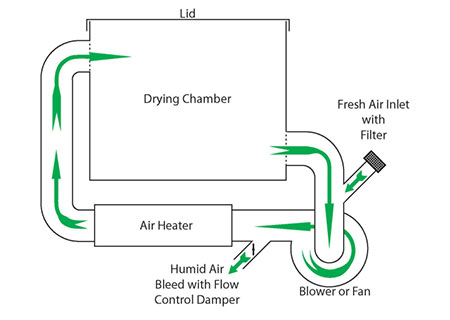

①Circulating hot air drying:

In this way, we can use thermal insulation material (such as firebrick) to build a drying chamber, with a fresh air inlet in the top and air intakes in the side. The air inlet is connected with the heating room which is made of iron sheet, the ground of which is insulate electricity and heated by electric stove wires of 3KW/220V (it also can be heated in the other ways). Then dryer dry the vibrating motor winding by blowing the hot air (the temperature of air should be controlled for about 100℃) in the heating room to the drying chamber.

②Chemical desiccant water absorption

Quick lime, which major element is calcium oxide, absorbs water by chemical reaction, which is irreversibility. Regardless of environment humidity, quick lime has the water absorb ability of more than 35% of itself weight. Quick lime is suited to preserve at low temperature and its price is low.

Besides, we can also put a high power incandescent bulb in the direct discharge vibrating sifter machine, but notice that keep the bulb away from wires.